KEYNOTE - In the beginning, there was water

Le 25 déc. 2023

By Grégory Quenet

In 1853, the term "startup" did not exist. However, this term describes the new Compagnie générale des eaux exactly: a risky innovation based on the anticipation of new uses for water that had not yet been identified as profitable markets. After 170 years of existence, a formula for success can often appear misleading. Nevertheless, to understand our current circumstances, we need to delve into the past, as it takes one to recognize another.

During an era of water scarcity, from the Middle Ages to the modern period, water was more a matter of prestige and power than of comfort and service. A strong body odor was seen as a sign of good health, while the line between what was considered healthy and unhealthy was primarily defined by morality and religion. Although there were already some disruptions to ecosystems caused by agriculture, craftsmanship, and human activities in general, no one worried much about the sanitary quality of water. For Parisians of the time period, the “Samaritaine” evoked the image of a machine built by Henry IV to provide water from the Seine to drink. In royal parks and in town, the French court prioritized water as a spectacle over everyday needs, which partly explains Paris's delay in developing a comprehensive water supply network when compared to London. compared to London. While everyone relied on three main sources—rivers and streams, capturing and transporting water from springs through aqueducts, and digging wells to access groundwater—social hierarchy determined the quantity of water available. In addition, everyone was subject to seasonal variations: low flows during summer and frozen water in winter.

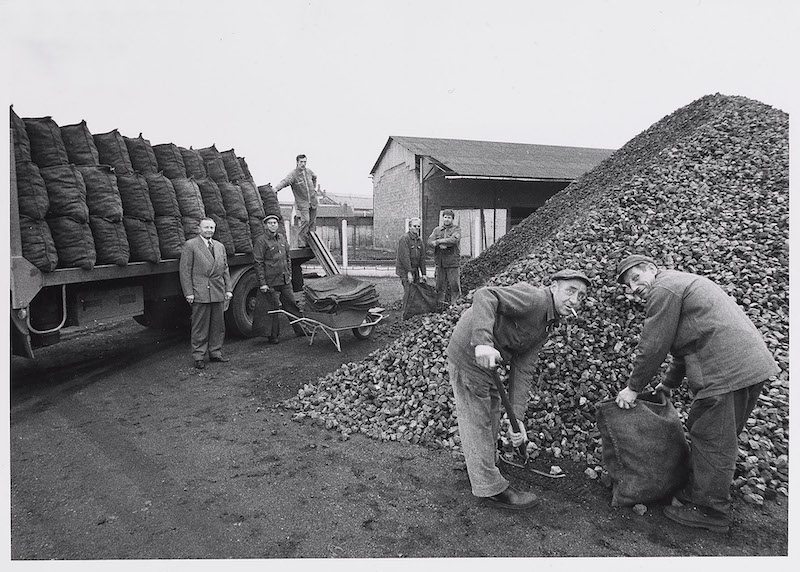

The first half of the 19th century witnessed an increase in water supply to households in English cities, but not in major French cities. The latter relied on passive hydraulic systems, using the hydrographic basin that naturally supplied water through gravity, whereas the cities of Albion used coal-powered pumping machines thanks to the abundance and low cost of coal. It was from a sense of Anglophilia that the early private water companies of Paris, such as the Compagnie des Eaux de Paris, founded by the Périer brothers, opted for these expensive machines (which operated until 1858) even while canal water did not seem able to generate much market value; their low maintenance cost gave the deceptive impression of an inexhaustible and almost free supply of water. Compared to England, Germany, and the United States, water became highly politicized, as its control became a source of rivalry between the French king and the city, and later between the State and the municipalities.

As a result, both the state and the king prioritized water for monumental and strategically important locations for the purpose of social control, and they had little interest in providing water services for all. If Paris, which benefited from a public network of drinking water and sewers, was an exception, it was again for political reasons; during the Second Empire, the aim was to surpass London in developing a comprehensive water supply network.

When the Compagnie générale des eaux became the first major French capitalist company to focus on general water distribution in cities, it was a gamble. However, it was based on successful examples in England and the United States and, more importantly, on the anticipation of society becoming increasingly water-dependent, putting an end to the era of water scarcity. The urban population in France increased from six million in 1831 to fifteen million in 1891, and then to twenty-nine million in 1954, in a country that was far behind in terms of urbanization compared to other Western European countries (19 percent of French citizens lived in cities in 1831 compared to 44 percent in Great Britain). This economic model proved successful, as it initially combined a profit margin of around 20 percent with a significant reduction in water costs for industries and individuals. For example, thanks to the distribution network of the Compagnie générale des eaux, the price per cubic meter dropped from 3.56 francs to 0.82 francs in Nantes in 1854, and from 5.55 francs to less than 1 franc after 1883 for the inhabitants of Rennes. The savings made on water carriers were substantial.

During the Belle Époque (the thirty-five years or so before the outbreak of the First World War), the company developed alongside the country by equipping major cities, tourist resorts on the Norman and Breton coasts, and finally the industrial cities of the north and east—not to mention the concessions in prominent cities abroad, such as Venice, Lausanne, Porto, and Constantinople. If, by the eve of the First World War, three quarters of French municipalities were under municipal management, it was because local elites had gradually and cautiously invested in water networks. The law authorized them to manage their own networks since needs were still relatively low in small communities, and expanding the number of water sources and water treatment was not a priority. The interwar period and, especially, the post-Second World War period bridged the gap between large cities and the rest of the country (only 37 percent of households had running water in 1946, compared to 97 percent in 1975). The system of multiple small local companies, ill-suited for this scale of demand, disappeared in favor of consolidated expertise.

The emergence of water-dependent societies caused a massive environmental transformation that had not been anticipated in any industrialized country or in the water sector itself, and as a consequence the sector became much more complex. The transition from a few liters to hundreds of liters of consumption per day per person disrupted ecosystems, intensifying the circulation of pollutants and microbes. Thus the water distribution business became intertwined with water treatment, which led in turn to the question of waste and its collection, then to its transportation, then its valorization and incineration, and ultimately, to energy. Therefore, the Compagnie générale des eaux grew through the fusion of different needs, which, with each newly acquired market, merged in unique ways and generated new challenges. This constant adaptation, both in France and increasingly abroad, created a dialogue between the world of high-ranking engineers and that of the field and its stakeholders, where unforeseen difficulties, failures, and successes were all valuable lessons.

And this is where the flexibility of the French system shines. Instead of favoring a single model like private companies or municipal management, as in England and Germany, France's water management is characterized by a three-way interplay between the State, municipalities, and private entities. The rules of this game are constantly negotiated, combining the long-term perspective of investments and techniques, the medium-term perspective of new needs and their environmental impact, and the short-term perspective of crises and bills. It is a unique way to manage this common commodity—water—and involves various legal forms of private involvement based on the services required.

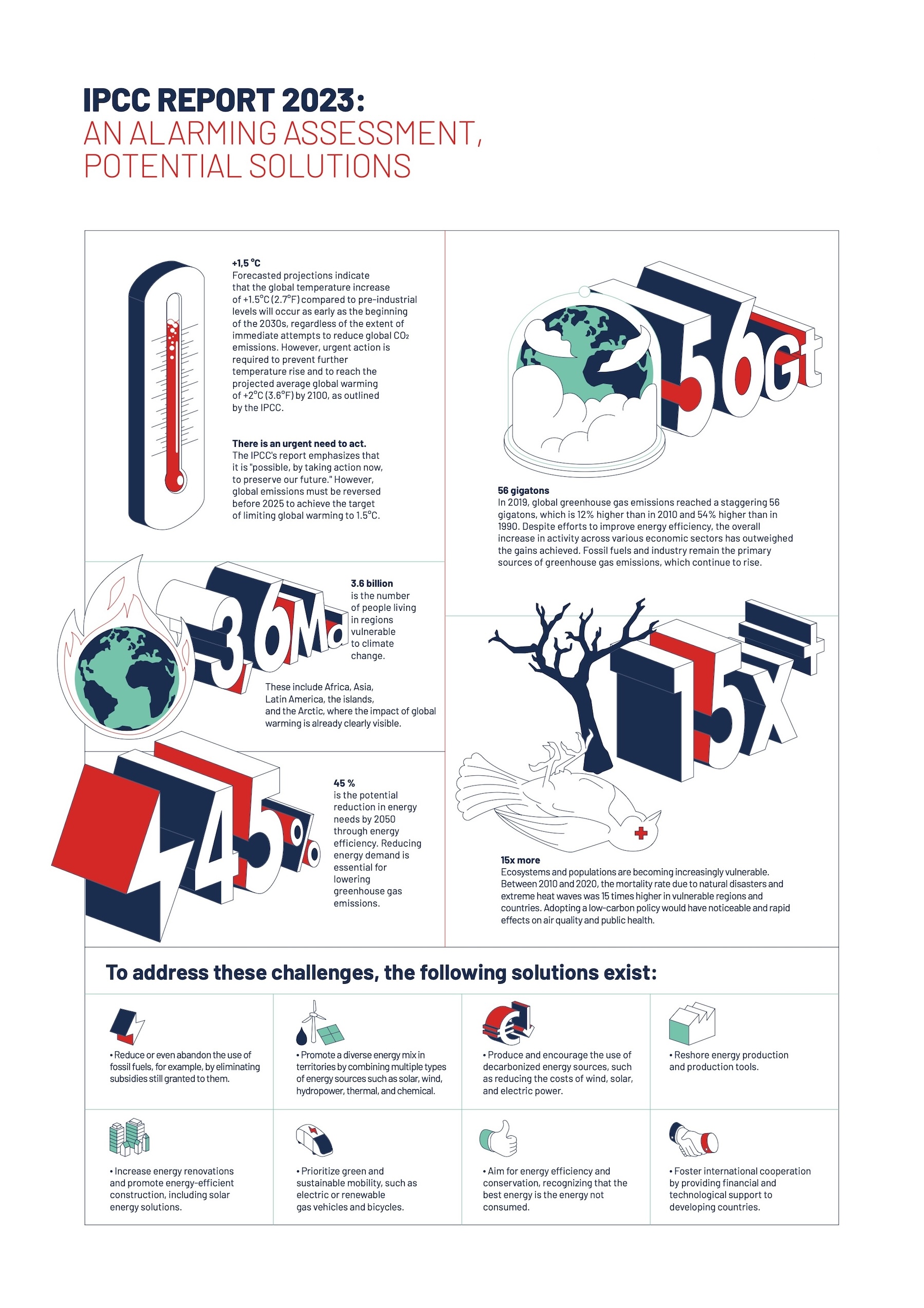

As we enter a new water cycle, it is essential to understand how Veolia’s history is deeply intertwined with the water journey: from scarce and aristocratic water to water-dependent and polluting societies. Paradoxically, society’s ability to respond to these challenges in the most privileged areas of the world has led us to overlook the scale of the transformations and difficulties that have been overcome, making networks and hybridizations invisible and creating the illusion of an abstract and readily available water supply without mediation. Today, just as in 1853, the companies that will thrive are those that can adapt—in this case, by anticipating a new era of water efficiency and sustainability. The response to climate and environmental changes is primarily anthropological and cultural, from which technical advancements, regulations, and new markets will emerge.

The Environment's Prelude

The word "environment" appeared in French—fleetingly referenced by geographer Paul Vidal de la Blache in the early twentieth century—as a translation from English. However, it had entered common language by the 1960s. This decade marked the institutionalization of ecological issues in industrialized countries, as illustrated by the creation of the first Ministry of the Environment in the UK in 1970, followed by the second such ministry, in France. Established a year later, the French ministry was named the "Ministry for the Protection of Nature and the Environment."

The English usage combines two meanings. On one hand, it refers to the physical context that influences life forms. On the other hand, it represents something that humans did not create and therefore need to understand and protect using the tools of natural sciences. This concept is linked to the term "ecology," which has a different history—the creation of a new scientific discipline in 1866 by Ernst Haeckel, based on the Greek root "oikos," meaning "house," before later referring to nature conservation movements in the 1960s.

These nature conservation movements soon found their political expressions: the first green party, the Values Party, was established in 1972 in New Zealand, followed by the British Ecology Party in 1973, and Ecology and Survival in France the same year, which many activists wanted to engage in partisan action. In the Western context of post-World War II modernization, the term "environment" referred to a set of problems that needed to be addressed. Initially, it focused on urban planning, but increasingly expanded to encompass ecosystems affected by modernization.

While the French Ministry of the Environment initially concentrated on addressing noise pollution (a new issue in the rapidly transforming cities), the fight against other forms of pollution and the protection of natural spaces quickly became central. This period of history demonstrates how the concept of "environment" evolved, adding existing public policies to the aggregate expertise of technocrats and engineers in order to address new issues as they emerged on the institutional agenda.

In the first Que sais-je?1 book dedicated to the environment, published in 1971, geographer Pierre George acknowledged the versatile and holistic nature of the idea, which even included the sense of "artistic installation" during that time. The term "biodiversity" appeared later, in the late 1980s, with the mobilization of conservation ecologists, though the creation of the Intergovernmental Panel on Climate Change (IPCC) in 1988 initially received little public attention.

This commonly told history of environmentalism gives little space to companies, which are often seen as arriving after these developments, using an already mature science to respond to public demand. Veolia's history shows that this is not the case and that the private sector's contribution to the creation of new knowledge and tools needs to be acknowledged.

The establishment of the Compagnie générale des eaux in 1853 addressed a blind spot in public policies: the need to provide water to households. Moreover, the company's development was made possible by an initially unidentified nuisance: the increase in polluted water volume. But even more interestingly, the company's history reveals the early aggregation of environmental problems to be solved, anticipating the use of the term "environment" and leading to the proposal of new sanitary services a century before the creation of various governmental ministries of the environment.

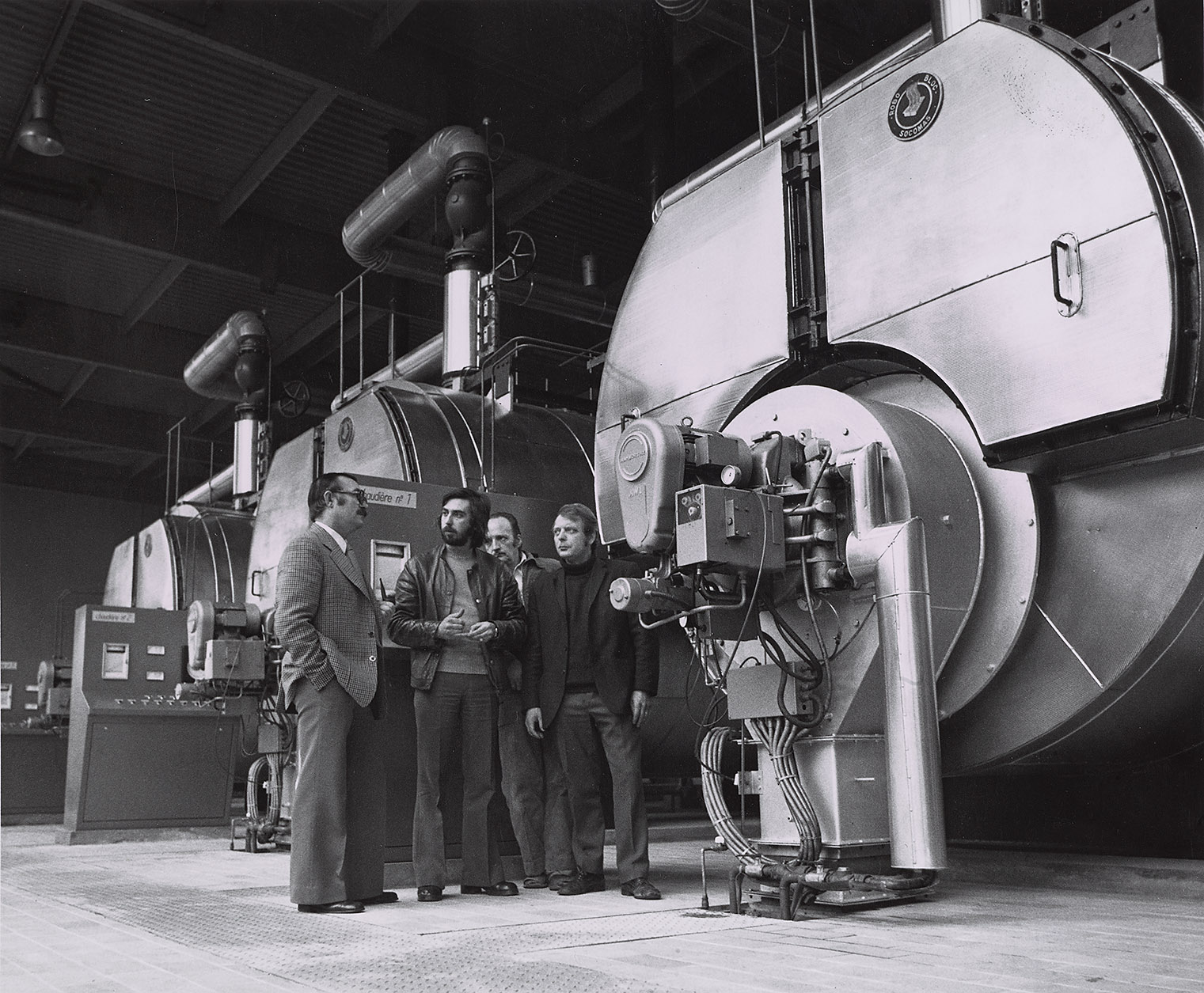

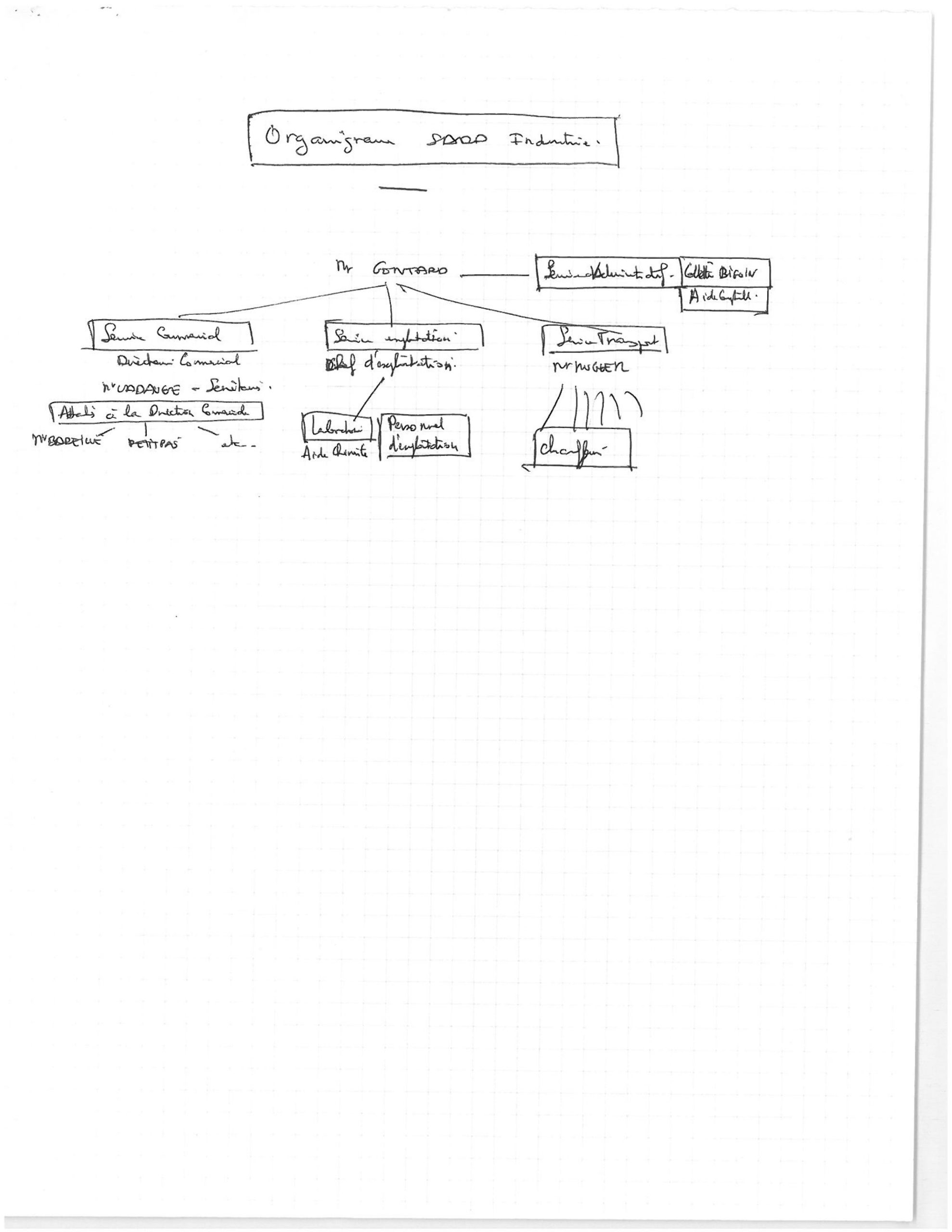

Water pollution led to waste collection and later to industrial waste treatment. In doing so, the company identified the second major nuisance that characterized the sanitary city after the Second Empire decided to marginalize the famous ragpickers. of Paris, putting an end to the systematic reuse of all human products. The classification of certain waste types resulted in the creation of SARP Industries in 1975 to handle hazardous waste. Waste issues led to the integration of waste management and transportation companies, such as Grandjouan, established in Nantes in 1867, and the Compagnie générale d'entreprises automobiles (CGEA), fully integrated in 1980, operating in the municipal waste and urban transportation sectors.

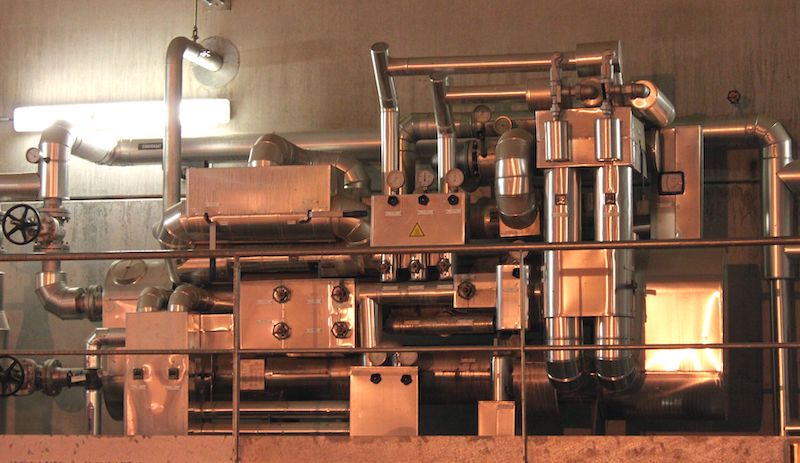

While the integration of transportation within the scope of environmental ministries remains a point of tension today, Veolia made the strategic decision not to include transportation activities within the company, focusing instead on resource management. Incineration became an alternative to spreading waste, as was practiced in Germany and England. In France, SEPIA (Société d'entreprises pour l'industrie et l'agriculture) and Union des services publics, two companies specializing in waste management, joined the group in 1980, the same year that the Compagnie générale des eaux gained full control of the Compagnie générale de chauffe (CGC), with which it had been operating incinerators since 1967. This led to the development of the energy sector.

The company’s approach—accompanying ecological transformation from its inception—is reflected in a very particular way. The company adapts to evolving environmental issues by continuously inventing new technical, legal, financial, and conceptual tools. The current rise of the energy sector, more in line with the pillars of ecological transformation, demonstrates that this story, in which the company transforms itself to meet contemporary needs, is never finished. Some pages from the company's history, now closed, illustrate this adaptive capacity, which always emerges on the local scale. The investment in the public works sector through the acquisition of Société générale d'entreprises (SGE) in 1988 was a strategic response to a stock market takeover bid, but it was also tied to the establishment of networks and the construction of serviced buildings. The integrated management of services at the building level renews the question of energy renovation and construction methods, while the growing importance of digital technologies multiplies the flows that need to be managed. In telecommunications and media, the logic of flows prevails: if water passes through certain areas, why not also pass cables and, subsequently, content?

This constant adaptation, as expressed through the company’s strategic vision, requires a careful balancing act. On the one hand, the big-picture, present almost from the beginning, is driven by the challenge of finding local solutions for each unique context, from which the company must continually learn. For example, the concession of water in Venice in 1879 necessitated the invention of installations capable of passing under the Grand Canal, while in 1893, there was a project to develop purification using potassium or sodium permanganate for hot-weather cities like Saint-Louis in Senegal. On the other hand, and as these examples demonstrate, the international expansion of a French group, based on a different model from that of England, Germany, or the United States, has required it to adapt to distinct national contexts and invent solutions that, in turn, may transform the group's practices. The establishment of the group in Dubai, for example, significantly accelerated the development of digital applications dedicated to customer relationship management and contractual innovations related to energy performance. How do information and innovation constantly circulate to adapt an initial frame of reference to local and international perspectives? Internally, employees have a form of prescience at their respective levels, but these stories, with their successes and failures, deserve to be shared more frequently with the public.

A company is also a living memory, which becomes especially important as challenges re-present themselves on every scale: climate change is accelerating, pollution is reaching the limits of the Earth’s ecosystem, and resource scarcity is intensifying. This is a new chapter in a history that dates back to 1853, addressing human responsibility in redefining the relationships between all entities that inhabit the Earth while also redefining the meaning of prosperity. This reflection brings us back to the origins of the word "environment." While the initial etymological research pointed to English, "environment" is actually a French word introduced to England by the Normans in the 12th century, only to gradually be forgotten in France and later retranslated in the opposite direction. In medieval French, it referred to what "surrounded" a house—barriers or enclosures. So in essence, it encompasses all the connections with water, soil, living beings, and climate—connections that we need to relearn if we are to continue inhabiting the Earth.

Reconnecting and Unifying the World

Far from being a detached exercise, the study of history allows us to use the past to envision the future. By understanding where we come from and our contribution to the history of the environment, we can grasp the requirements of a new era. The most recent transformations of the former Compagnie générale des eaux demonstrate how its original identity has been maintained throughout its evolution. This predominantly French group, which had withdrawn from international markets after the financial setbacks of World War I, reestablished itself internationally in the 1990s. However, this happened in a completely different context and with unprecedented intensity.

The collapse of the Eastern Bloc in 1989 and the rise of emerging countries facilitated by globalization reshaped the global map of environmental service needs. The ideals of health, safety, and comfort that were prevalent in industrialized countries became widespread: the middle class grew from one billion individuals in 1985 to two billion in 2006, three billion in 2015, and four billion in 2021. The geography of this middle class also changed: in 2000, 80 percent of it lived in Europe and America, but that figure dropped to 35 percent by 2015.

Veolia accompanied these transformations in countries where almost everything had to be built from local cultures with their unique needs and strengths. Difficulties were not uncommon, but the ability to learn from local needs (present from the very beginning of Compagnie générale des eaux) proved to be an advantage. Unlike most sectors, which can deploy standardized solutions on a global scale, environmental services are based on localized assemblies of humans and non-humans, an inseparable arrangement of materiality and culture that varies from place to place. In this domain, made highly sensitive by its involvement with essential human needs, governance ensures transparency and guarantees quality. However, it also needs to operate with flexibility, refraining from placing limitations on human resources or their solutions.

This significant change occurred against the backdrop of triumphant globalization, where production processes have often been fragmented and relocated to achieve economies of scale. However, what used to be a collection of environmental problems with separate stories (water, waste, energy) has become increasingly interconnected. Starting from its establishment in new territories to meet specific needs, the company has created synergies.

In Asia, particularly in China and Japan, the focus on energy has led to the development of cogeneration and steam networks, later benefiting water for cooling purposes. In Eastern Europe, the need to establish water distribution and treatment networks took advantage of the local expertise in heat production. In Brazil, the management of endless waste has resulted in local energy production. Unbeknownst to anyone involved at the time, what had happened in France was being replicated on a larger scale wherever it was necessary to operate in a new region.

While the Compagnie Générale des Eaux had developed during the progressive interruption of society’s organic metabolism from the Ancien Régime, circularity has been reintroduced—but in a new way, as there is no longer an immediate connection to natural elements. Even in the 1850s, pure water had long ceased to be available on-site: the sanitary needs of urban expansion required fetching water from far away, then purifying it and prohibiting the spreading of raw organic waste downstream, creating a new linearity. When Veolia began operating in new countries during its internationalization of the 1990s and 2000s, it became quite different, as hybridizations were legally possible and even desirable. Innovations within the group thus ceased to circulate solely from France to the international arena and instead spread from all countries in all directions, enriching the group’s practices based on lessons learned in the new areas of growth.

The ecological challenge of climate change requires us to address a unique global issue within the infinite diversity of human societies. In other words, we have to connect two theoretically irreconcilable scales by inventing a new way of proceeding: decentralized management based on the circularity of material and energy flows. The companies accustomed to working on very concrete and localized processes while mastering the entire decarbonization chain will be the winners. It is an approach that is more qualitative than quantitative, relying on the field teams.

This “landing,” to use Bruno Latour's term, is a rediscovery of geography, history, and the human beings attached to them. The lessons of history will be easier to implement for companies that have never forgotten them. However, it is no longer just about addressing industrial and institutional clients: the gradually growing awareness has given rise to demanding public opinion. And this public demands proof that mitigation and adaptation can be reconciled while reinventing an ideal of prosperity.

- Que sais-je? is an editorial collection published by the Presses universitaires de France. ↩︎